Amprius SA08 in Drones: A Battery Engineer's Guide Beyond the Typical Datasheet

- About:Energy

- Jul 11, 2025

- 9 min read

Updated: Nov 6, 2025

The Amprius SA08 is a high-specific-energy lithium-ion pouch cell designed for aerospace-grade drones, offering 338 Wh/kg while weighing just 108.5 g. In this blog, we use About:Energy’s lab-validated electrical model to simulate the SA08 under real multicopter drone loads—revealing voltage behaviour, heat generation, and usable energy beyond what the datasheet shows.

Introduction: Amprius SA08 Datasheet Limitations

The Amprius SA08 is an ultra-lightweight lithium-ion pouch cell developed for aerospace-grade drones where energy-to-weight ratio is critical.

Leveraging silicon anode technology, Amprius has pushed the boundaries of gravimetric performance, offering a compelling solution for UAVs requiring extended range or greater payload capacity.

It delivers 10.8 Ah at a nominal voltage of 3.4 V, with 36.7 Wh of energy. The cell has a maximum weight of 108.5 g and occupies 50.3 cm³, yielding a minimum gravimetric energy density of 338 Wh/kg and a volumetric energy density of 730 Wh/L. To ensure consistency across manufacturers, The Voltt reports energy density based on maximum cell weight. In practice, this cell typically achieves 345 Wh/kg, with a maximum value of up to 351 Wh/kg. The high specific energy makes it a standout choice in applications where flight time, mission endurance, or vertical take-off weight are constrained.

This blog applies About:Energy’s lab-tested electrical models to simulate how the SA08 performs under dynamic load conditions typical of multicopter drones. We explore voltage behaviour, heat generation, and impact on usable energy under real-world use cases to help engineers evaluate performance beyond just the datasheet.

Even with a detailed datasheet, engineers lack visibility into how battery behaves under dynamic or edge-case conditions. Key performance factors, such as temperature rise, rate capability, and voltage polarisation, only emerge under realistic operating scenarios.

That’s when cell simulation plays a critical role. It helps validate a cell's capability beyond standard lab data and ensures cell selection decisions are informed by application-specific insights. Below we run simulations in application-relevant conditions such as constant current, constant power, and a drone drive cycle to assess cell performance.

The Voltt is our cell selection and simulation platform that cuts the time to identify the right battery for your programme by up to 70%. It combines high-precision laboratory data with powerful models, enabling engineers to directly compare electrical and thermal characteristics across cells. Make faster, more confident design decisions with trusted data — from performance insights to pack-level implications.

Start exploring advanced battery data and models like the Amprius SA08 with a 14-day free trial of The Voltt

Simulated Performance Data: Constant Current Discharge

To support early-state benchmarking, design and performance estimation, we simulated the Amprius SA08 under four constant current discharge rates: 0.5C, 1C, 3C, and 5C. This analysis provides insight into energy delivery, thermal behaviour, and electrical response, helping engineers define the operating envelope of the cell before investing in hardware testing.

At 0.5C and 1C, the cell demonstrates stable voltage behaviour, with average voltages of 3.42 V and 3.37 V respectively. Capacity utilisation remains high—over 98% of the SOC range—with total energy throughput reaching 37.9 Wh at 0.5C and 36.9 Wh at 1C. Under natural convection cooling conditions, temperature rise is minimal (ΔT of 2 °C and 5 °C), and heat generation remains low, with averages of 1 W and 2.6 W. Thermal efficiency is above 93%, indicating strong conversion efficiency across low-rate conditions.

At 3C, polarisation effects begin to shape the voltage curve more significantly. Average voltage drops to 3.26 V, and total energy throughput reduces to 34.2 Wh. Heat generation increases to an average of 12.2 W, and temperature peaks at 43 °C. Cooling demand also rises, with an average cooling power of 10.6 W. The cell still delivers 94.7% of the available SOC, offering useful energy at faster discharge rates within expected thermal limits.

At 5C, the discharge duration shortens further, with capacity accessed down to 6.5% SOC. Average voltage falls to 3.19 V, with energy throughput reaching 32.9 Wh. The cell reaches a peak temperature of 56.4 °C, with heat generation averaging 24.7 W and peak thermal output at 33 W.

Thermal efficiency remains relatively high at 87.4%, suggesting that despite the increased heat, the cell remains effective at converting stored energy into output power.

These insights help engineers understand how the SA08 performs across different C-rates: mapping the trade-offs between available energy, temperature rise, and heat rejection needs. This data can be used to size cooling systems, estimate mission duration, or validate whether the cell’s performance remains within target conditions at elevated discharge rates—all before committing to physical prototyping.

Why this matters

For engineers working on early-stage design of aerospace-grade drone battery systems, these simulations offer a fast and structured way to assess whether the Amprius SA08 meets mission requirements.

By quantifying capacity retention, voltage polarisation, and thermal behaviour across a range of discharge rates, teams can make informed decisions on pack sizing, current limits, and cooling strategy—before committing to physical testing.

Without this data, understanding how the cell responds at 3C or 5C would require extensive lab work. Instead, engineers can rapidly compare energy delivery and heat generation under different load conditions, reducing the time and cost of down selecting viable cells.

Operating Conditions

Initial SoC: 100%

Initial Cell Temperature: 25 °C

Heat Transfer Coefficient: 50 W/m²·K

These conditions reflect moderate passive cooling (e.g., air flow across cylindrical cells), which is more representative of drone enclosures than idealised thermal chambers. This makes the data more realistic and actionable for system-level cell selection decisions.

Simulated Performance Data: Constant Power Discharge

While constant current testing provides baseline insights, many drone systems operate under defined power demands—whether for propulsion, comms, or payload. Simulating constant power discharge reveals how the Amprius SA08 responds under these realistic conditions, especially across varying load levels that affect system design decisions.

We tested the cell at 25 W, 50 W, 75 W, and 100 W. At 25 W, the SA08 achieves near-full energy output—37.3 Wh—with minimal voltage polarisation and 99.1% of SOC accessed. The average voltage remains high at 3.45 V, and peak temperature stays below 30 °C. Heat generation is minimal, averaging just 1.5 W with high thermal efficiency (94.3%).

This suggests excellent suitability for long-endurance, low-load drone missions without substantial cooling demands.

At 50 W, the average voltage drops slightly to 3.4 V, with 35.8 Wh delivered. The cell reaches a peak temperature of 35 °C with average heat generation at 4.1 W. Even at this mid-power level, thermal performance remains well within manageable bounds, and thermal efficiency stays above 92%.

At 75 W and 100 W, the cell’s behaviour reflects the increasing impact of internal resistance. Voltage declines faster—averaging 3.35 V and 3.32 V respectively—and discharge time shortens considerably. Delivered energy decreases to 34.7 Wh (75 W) and 33.8 Wh (100 W), with current ramping to 30–40 A in the latter case. Peak temperatures rise to 40.4 °C at 75 W and 45.5 °C at 100 W. Heat generation reaches an average of 7.5 W and 11.2 W respectively, with thermal efficiency falling slightly to ~90%.

Why this matters

These results show that the Amprius SA08 maintains strong performance and thermal control across a wide power range. For engineers designing propulsion or mission-critical systems, these simulations provide a clear picture of how the cell behaves as power increases—from cell temperature and heat rejection, to SOC access and derating thresholds. This level of visibility supports more informed decisions around pack sizing, cooling strategy, and mission planning—without needing to perform weeks of hardware testing.

Operating Conditions

Initial SoC: 100%

Initial Cell Temperature: 25 °C

Heat Transfer Coefficient: 50 W/m²·K

These conditions reflect moderate passive cooling (e.g., air flow across cylindrical cells), which is more representative of drone enclosures than idealised thermal chambers. This makes the data more realistic and actionable for system-level cell selection decisions.

Simulated Performance Data: Real-World Drive Cycle in Drone Battery Pack

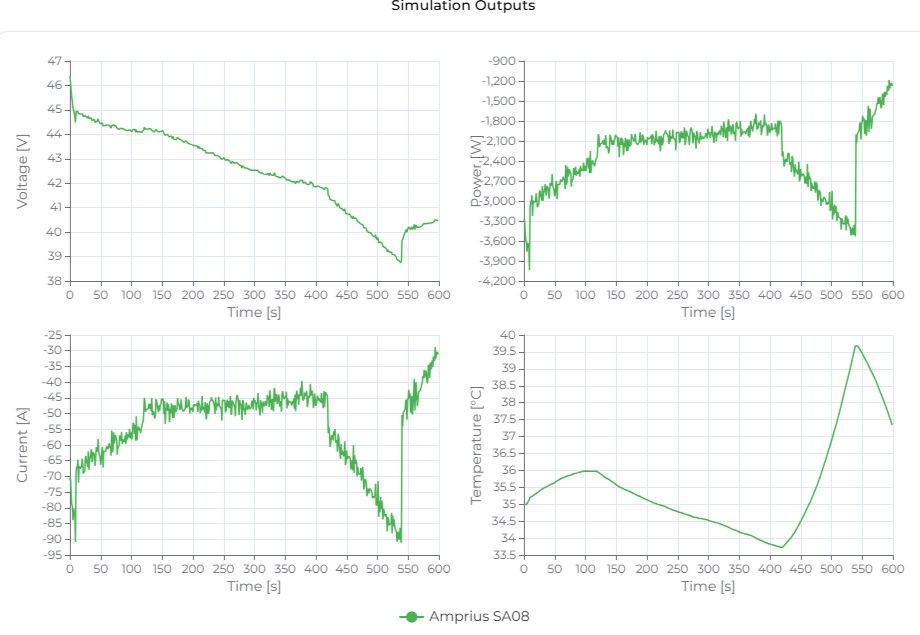

To evaluate how the Amprius SA08 performs in a real drone flight scenario, we configured a 12s2p pack and ran it through a scaled drone-style power cycle with rapid transients, hovering demands, and short recovery periods. This simulation helps engineers understand voltage recovery, thermal stability, and usable energy under dynamic load conditions—key for sizing and safety-critical applications.

The configured pack delivers:

Nominal Voltage: 12 × 3.4 V = 40.8 V

Capacity: 2 × 10.8 Ah = 21.6 Ah

Total Energy: 40.8 V × 21.6 Ah = 881 Wh

Estimated Pack Mass: 2.6 kg (with 108.5 g cells)

The simulated profile draws peak power exceeding 4.0 kW, with sustained output above 1.8 kW for much of the flight. Current ramps up rapidly during take-off and holds between 50–70 A for the majority of the cycle, peaking near 90 A. Voltage declines steadily with minor recovery periods, before a final dip at ~540 s triggers the 3.0 V/cell cut-off.

Thermally, the pack starts at 35 °C and reaches a peak of 39.6 °C near the end of flight. Temperature initially rises in the first 100 s, plateaus, and then increases again as current demand surges. The cell remains within comfortable thermal margins throughout, well below the 70 °C cut-off.

These results show that the SA08 is capable of supporting high-power drone manoeuvres for nearly 9 minutes (546 s) while maintaining thermal stability and providing over 90% of the accessible capacity.

Importantly, the system avoids thermal runaway, and no cut-off limits are breached—suggesting this configuration meets performance and safety expectations for aggressive short missions.

Why this matters

Dynamic simulations like this provide the clearest picture of how a cell performs in real flight conditions.

For engineers designing drone systems, this approach goes beyond basic capacity or peak power—revealing how the battery responds to rapid load shifts, sustained discharge, and heat accumulation. It highlights whether a pack maintains safe voltage margins, stays within thermal limits, and delivers the energy required for the mission.

These insights help teams make better-informed choices about cell selection, cooling design, and reserve strategy—well before physical testing begins. In airborne systems where weight, energy, and reliability are tightly constrained, understanding these dynamics early is essential. Simulation allows you to define your flight envelope, test emergency cut-off behaviour, and optimise around the latest high-performance cells—before a single prototype takes off.

Operating Conditions

Initial SoC: 90%

Initial Cell Temperature: 35 °C

Ambient Temperature: 20 °C

Heat Transfer Coefficient: 30 W/m²·K

Cut-Off Voltage: 3.0 V/cell

Temperature Cut-Off: 70 °C

These conditions were selected to mimic a partial-SoC flight that follows an initial take-off, with the battery already slightly warm from prior activity. The ambient temperature reflects a cooler flight environment, and the heat transfer coefficient represents passive convective air cooling while the drone is airborne. The 3.0 V cut-off provides an emergency buffer, ensuring telemetry and safety-critical systems remain powered in the event of near-complete discharge. The thermal limit of 70 °C was selected not as a hard safety threshold, but to preserve long-term cell lifetime under repeated load.

Summary of Simulated Findings Across All Test Cases

Across three simulation scenarios — constant current, constant power, and a dynamic drone drive cycle — the Amprius SA08 demonstrated consistent high energy delivery, stable voltage behaviour, and manageable thermal response under a range of demanding conditions.

In constant current testing, the cell maintained high capacity output and low temperature rise up to 3C. At 5C, increased polarisation and heat generation provided useful insight into the trade-off between power and energy availability, helping define practical current limits for design.

Constant power simulations showed that the SA08 retains strong performance across a wide range of loads. At 25 W and 50 W, the cell delivered near full capacity with minimal thermal load. At 100 W, it still accessed over 90 percent of its energy, while staying below 46 degrees Celsius, indicating suitability for propulsion or mission payloads under tight thermal constraints.

In the drone drive cycle simulation, a 12s2p pack built from SA08 cells powered a realistic flight profile with peak power exceeding 3.8 kW and average currents above 50 A. Over an 8-9 minute cycle, the pack maintained stable voltage and remained thermally controlled, peaking just under 40 °C. The system never breached voltage or thermal cut-offs, even with aggressive transients and short recovery periods. This gives engineers a close approximation of how the pack would perform in a real aircraft system.

Taken together, these findings show how simulation offers critical insights for early-stage battery selection and pack design. Engineers can assess thermal headroom, discharge behaviour, and usable energy without relying on hardware testing alone — supporting faster iteration and more confident system development.

Conclusion

From constant current and power tests to dynamic drone flight simulation, the Amprius SA08 has shown it can support high-performance, weight-sensitive systems with consistent electrical and thermal behaviour. It combines high specific energy with stable voltage response and acceptable heat generation across a wide range of load profiles.

More importantly, these insights are available before any physical prototype is built. With validated simulation models based on precision lab data, engineering teams can evaluate performance under real mission conditions in hours, not weeks. You can explore where voltage dips occur, how fast heat builds, and how much energy remains at critical cut-off thresholds — all without spinning up a single test rig.

This approach enables better decisions about cell selection, cooling design, and pack sizing early in the development process. It reduces risk, saves time, and helps integrate advanced cells like the SA08 into flight-ready systems with greater confidence.

Simulation is no longer a nice-to-have. It is a smarter, faster path to battery innovation.

What next?

Want to run your own Amprius SA08 simulations or test it against another high-power cell? Simulate is our virtual battery cycler tool made for faster cell selection, hosted on our platform called the Voltt.

You can simulate voltage and temperature response of a cell under any given duty cycle – in seconds.

Learn more about Simulate here: aboutenergy.io/simulate

At About:Energy, we specialise in cell degradation testing, and simulation. Our data and models allow accurate forecasting of capacity fade and resistance growth during operation - allowing customers to design Battery Management Systems, size thermal systems, and ensure their performance requirements are met across the lifetime of their products.

If you’re interested in learning more about how our models can help you, book a demo here.

Further reading:

Debating between the Molicel P45B and P50B?

Read: State-of-Health Assessment of the Molicel P45B: How Long Will My eVTOL Battery Last?

Reduced development time by 70%: McMurtry Case Study

Read our Forbes Feature